The source of fiber dyeing performance

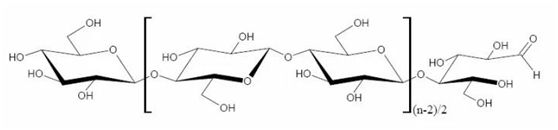

The good dyeing performance of fiber means that it can be dyed with different dyestuffs. When dyed with similar dyestuffs, it has the characteristics of bright color, complete chromatogram, uniform color tone, good color fastness, and mild dyeing conditions. Natural fibers and recycled fibers are easier to be dyed. Firstly, because their molecular structure contains functional groups that can be combined with dyestuffs, such as cellulose fibers have hydroxyl groups, they can form strong hydrogen bonds and ionic bonds with the hydroxyl groups, carboxyl groups, and amino groups of dyestuffs, and form with reactive dyestuffs, Covalent bonding; There are groups such as carboxyl and amino groups in the molecular structure of wool and silk, which can form a strong chemical bond with the basic or acid groups of the dyestuff, or can form a covalent bond with the reactive dyestuff. On the other hand, organic fibers generally have a certain pore or capillary structure, which is conducive to the diffusion of dye molecules in the solution into the fiber. In this way, natural fibers can be easily dyed in different shades and colorful colors.

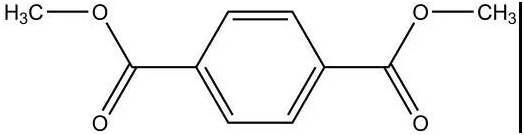

Among synthetic fibers, in addition to polyamide fibers and polyacrylonitrile fibers are easier to dye, most synthetic fibers are difficult to dye. This is because there are few or no functional groups in the molecular structure of the synthetic fiber that can easily bind to the dye. Synthetic fibers generally have a high degree of orientation, crystallinity or a dense skin structure, poor water absorption, and dye molecules are not easy to diffuse into the fiber, so it is difficult to dye synthetic fibers.

Relationship between fiber chemical composition and dyeing properties

The chemical composition of the fiber, that is, the molecular structure, determines to a large extent the type of dye it is most suitable for and the diffusion mode of the dye in the fiber.

In the relationship between the chemical composition of the fiber and the dyeing performance, the hygroscopicity of the fiber plays an important role. Generally speaking, hydrophilic fibers are dyed with water-soluble dyes, and hydrophobic fibers are suitable for dyeing with nonionic dyes. Fibers between the two can be dyed with ionic and nonionic dyes. The dyeing process mainly involves the fiber’s ability to adsorb dye molecules and the diffusion rate of the dye molecules in the fiber. Both of these determine the dyeing speed of the fiber, and the diffusion rate of the dye in the fiber is the key factor controlling the dyeing speed. From the point of view of dyeing conditions and diffusion activation energy, the diffusion characteristics of dyes on fibers vary greatly with the hygroscopicity of the fibers. Hydrophilic fibers such as cotton, viscose fibers, and silk will swell relatively in water. They can be dyed with water-soluble dyes with a relatively high molecular weight. The dyeing temperature is generally lower, that is, the dye is at a lower temperature. Under the conditions, it can diffuse into the fiber, and the diffusion activation energy is low. Synthetic fibers of polyester and polyacrylonitrile have a low moisture absorption rate and rarely swell in water. Their dyeing needs to be carried out at a relatively high temperature, and the diffusion activation energy of the dye is relatively high.